METRO RUBBER CORPORATION -Industrial Rubber Sheets

METRO RUBBER CORPORATION -Industrial Rubber Sheets

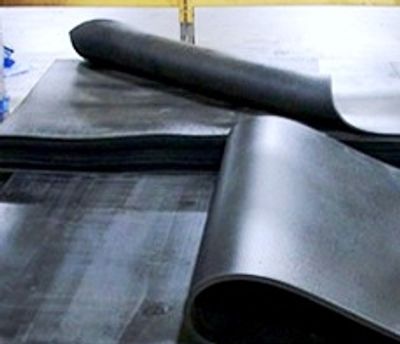

Acoustic Rubber Sheets

Sound proofing / Damping Rubber Sheets

Blended “Polychloroprene” elastomers have the property of distributing sound waves throughout the surface rather than reflecting them. Microscopic pores on the surface of Rubber sheets help absorb sound vibrations, therefore are being used for noise reduction purposes. These are high-density (more mass per sq. foot) flexible sheets ranging from 1mm to 12mm thick. Chloroprene polymer is often mixed with Synthetic resin, minerals & plasticizers to make it more economical & affordable for bulk use.

Sound Proofing/ damping sheets also called Mass Lorded vinyl (MLV) can be used in walls, ceilings & floors.

In walls, these can be pasted or punched with nails. However the best way is to make a particle board structure & install these sheets over it, this offers better performance.

The procedure for installation in the ceiling is the same as for walls, however, thin sheets are recommended for the ceiling since these are quite bulky.

Rolls of acoustic Sheets of relatively higher thickness can easily be installed on concrete floors. These are flexible & can be cut easily in desired shapes, making installation easy for stairs & corners.

Features:

- Efficiently control high, medium & low-frequency waves.

- Control vibration due to foot movement over the floor.

- Prevent seepage from surrounding walls/underground water.

- Anti-aging, generally service life is more than the building structure itself.

- Cost-effective & efficient compared to other relevant alternatives such as Rockwool/glass wool.

- Available in variable thickness, width & length.

- Flexible & compact, making it easy to install, especially in elevation, stairs & uneven surfaces.

Application: Movie Theaters, Offices, Airports, sound recording Studios, Material Testing rooms, auditoriums, hospitals, Gym, Night clubs, gen-sets canopy, air conditioner ducting, Ships & submarines, etc.

Composition: Vulcanized blend of Vinyl, Polychloro based Rubber, plasticizers, carbon & minerals such as Calcium Carbonate.

Size:

- Width: up to 1500mm.

- Thickness: 1mm to 12mm (higher thickness can be manufactured upon order).

- Length: 10mtr per roll.

Surface: Smooth on both sides OR Rugged on one or both sides.

Technical Specifications:

- Specific Gravity (gm. / cm3) 1.80-2.10

- Hardness (Shore A, ±5) 75

- Elongation at break, min (%) 150

- Compression Set, at 70°C for 22 hrs. (%) 25

- Service Temperature Range -40° C to +90° C

- Tensile Strength, min (kg /cm2) 25