METRO RUBBER CORPORATION -Industrial Rubber Sheets

METRO RUBBER CORPORATION -Industrial Rubber Sheets

Natural Rubber Sheet

Natural rubber sheets are prepared by sulfur-heat-based curing of dried latex (which is a thick milky-white emulation extracted from the bark of rubber plants) compounded with added minerals, additives, and accelerators. Unlike synthetic rubbers, which are petroleum-based rubbers, it is derived from plants and however slowly but biodegradable.

Pure gum-grade sheets made from natural rubber bear high tensile strength and elongation with adequate flexibility, offering extreme resistivity against abrasion and mechanical distortion.

Properties of Natural rubber :

- Offer excellent physical and mechanical properties: high elongation (up to 800%) and tensile strength (up to 19 MPa).

- Good elasticity and excellent compressibility,

- It mixes well with pigments and thus can be made available in a variety of colors,

- High resistance to tearing and abrasion

- Non-slippery, high friction coefficient,

- Anti-fatigue and good cushioning properties,

- Excellent adhesion to the metallic surface,

- Can be customized in a broad hardness range (from 38 to 90 on a Shore "A" scale),

- Good at sound and vibration damping,

- Economical compared to synthetic elastomers,

We manufacture Natural sheets in various grades, from low-cost "commercial or economical grade" to "pure-gum premium grade" quality based on compound composition. Often, recycled rubber and minerals like calcium carbonate and China clay are added in excess to it to make it more economical.

Application:

Skirt-board for conveyor belts, anti-fatigue mats, shot blasting, electric insulation, sound damping, anti-vibration pads, shooting-range ballistic sheets, gym flooring, yoga mats, mattress protector sheets, packing, and sealing.

Size: width x length: 1 meter x 2 meters, 1.2 meters x long length, 1.5 meters x long length, or as per requirement.

Thickness: NR rubber sheets are available in 1 mm to 50 mm thickness.

Surface: smooth on both sides, or fabric impression on one or both sides.

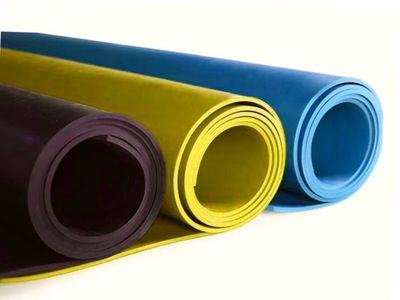

Color: Mostly black, but other colors such as red, green, blue, honey, tan, and white can be made available.

Technical Specifications: Natural rubber sheets can be manufactured as per the mentioned properties and variations, depending upon application's requirement.

- Specific Gravity (gm/cm3) 1.05 to 1.90

- Hardness (Shore A, ±5) 38 to 95

- Tensile Strength, (kg/cm2) up to 190

- Elongation at break, (%) up to 800

- Compression set at 70 °C for 22 hours, 40 to 45

- Service Temperature Range, -55 °C to +85 °C

Natural Rubber Sheets could also be offered with one, two, or more Nylon Fabric or Steel Wire Mesh Reinforcement Layers to be used where the sheet is subjected to extensive hydraulic or pneumatic pressure, called Insertion Jointing Sheets (IS: 638-1979).

*It degrades under petrochemicals and is therefore not recommended for petroleum or oil applications.